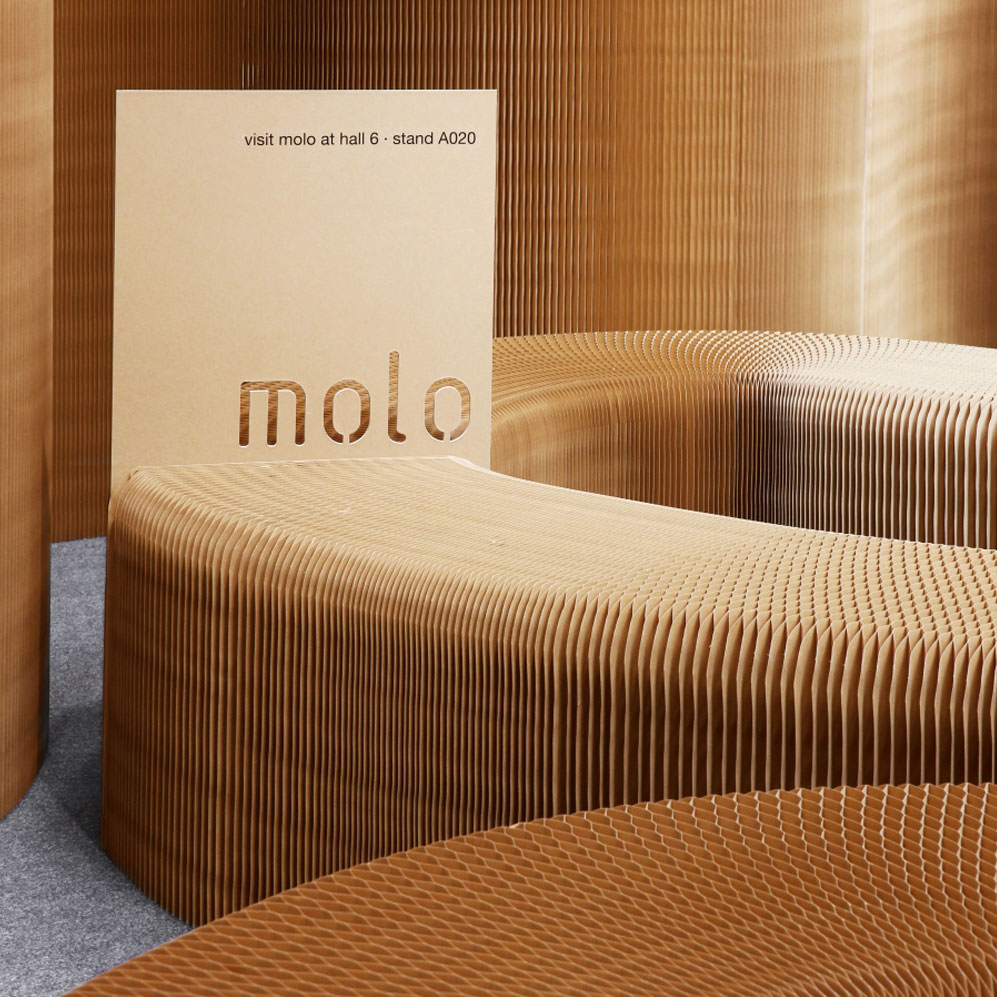

utterly flexibly and reshapable, ever wonder how honeycomb paper furniture came to be? Back in the Fall of 2015, the writers at The Plus magazine got their opportunity to catch up with Stephanie Forsythe for a deeper Q&A conversation on the origins of their ground-breaking idea, early tests and prototypes, and how they got the idea to apply honeycomb geometry to the product’s structure.

we selected a few nice excerpts from the article and interview that we found both surprising and inspiring (links to the full article below).

the prototype story

as the story goes, after Stephanie Forsythe and her husband Todd MacAllen finished architecture school; they ditched their careers in the design/build field and decided to step away from client work. After selling their tools as a result of having to get by, the pair began creating tiny models out of paper. As their experiments became more refined, they transitioned paper for more traditional materials. The pivotal result, a life-sized prototype of the softwall made entirely of tissue paper.

Says Stephanie Forsythe:

“we didn’t expect it to do what it did, it was about 60 feet long, and we couldn’t believe it!”

The Plus: What was the initial concept when creating molo?

SF: I think one of the things we were really interested in was flexibility in all different types of buildings. For example being able to fold away a bedroom, to give some space back to the family, ... [since] life is constantly evolving, ... we wanted to create things that were able to shift and transform as people worked or lived in different ways.

The Plus: You started with tissue paper, what kind of paper do you use now?

SF: The paper we use is 50% recycled cardboard boxes, and 50% northern tree paper. Northern trees have long fibers as they grow slower, which is what gives the pieces such durability. If we used 100% recycled material the fibers would be too short so they would break down.

we have three materials, so in addition to paper, we have the one we use for lights, which is polyethylene. They can get wet; they’re extremely resistant and can’t be ripped if you tried. The third material is something we’ve developed that uses PET. It’s the same plastic that’s in water bottles.

we try to keep all of the materials we use at 100% so that at the end of its life it can easily be recycled. Everything is meant to be long term and not a disposable product. We also use a non-toxic salt-based fire retardant on our products.

The Plus: How did you get the idea to use the honeycomb method?

SF: Honeycombing is actually used in many places. However a lot of the honeycomb in the world is hidden, like in the hollow of a door, you won’t see it but it’s doing a very important structural job.

The Plus: What’s your favourite thing about your work?

SF: I think it’s the fact that while being flexible and versatile, it’s abstract enough too. There are so many people from different aesthetic backgrounds interested in our work. It’s amazing. We’ve sold to the army, to churches of many denominations, to high-end fashion houses. I think creating something that both the army and Hermes would buy is quite fascinating.”

read the full article by The Plus here.

see our more of our honeycomb paper furniture here.

see molo products in action around the world here.